The rapid advancements in computing technology have led to the rise of specialized platforms designed for high-performance applications. One such platform is the COM-HPC carrier, which is an integral part of modern embedded systems and edge computing devices. This guide provides an in-depth look at the COM-HPC carrier design guide, which helps engineers and developers create robust, high-performance systems using COM-HPC (Computer-on-Modules High-Performance Computing) technology.

Table of Contents

In this article, we will explore the key features of the COM-HPC platform, its design requirements, and the considerations necessary for creating effective carriers. Additionally, we will address some common questions and best practices to ensure optimal performance and compatibility.

What is COM-HPC?

Before diving into the COM-HPC carrier design guide, it is essential to understand the basics of COM-HPC technology. COM-HPC is a specification for high-performance embedded computing platforms. It builds upon the established COM (Computer-on-Module) standard, which allows for the separation of computing units from the carrier board, offering flexibility and scalability.

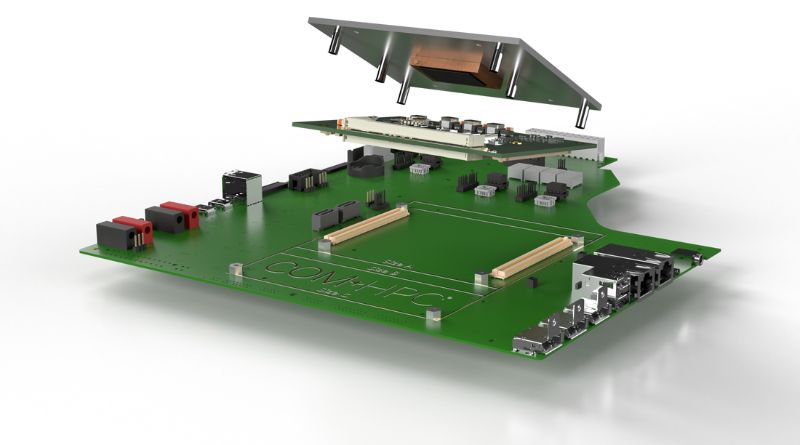

COM-HPC modules are used in a variety of applications, from edge computing and industrial automation to IoT (Internet of Things) devices and AI-powered systems. These modules integrate processors, memory, storage, and I/O interfaces in a compact, standardized form factor. The carrier board, on the other hand, is a custom design that interfaces with the COM-HPC module, providing power, signal routing, and connections to external devices.

COM-HPC was created to address the growing need for high-performance computing in embedded systems, offering a more powerful and flexible alternative to traditional embedded systems like COM Express. With this in mind, the COM-HPC carrier design guide is critical for building carrier boards that support the unique features and capabilities of COM-HPC modules.

Key Components of a COM-HPC Carrier Board

A COM-HPC carrier board provides the necessary connections and support for the COM-HPC module. These carrier boards typically include power supplies, connectors, and interfaces for peripherals. Some of the most important components and considerations for designing a COM-HPC carrier board include:

1. Power Supply Design

One of the first things to consider in the COM-HPC carrier design guide is the power supply. The COM-HPC module itself requires a stable power source, and the carrier board must supply this power in the required voltages. Depending on the module, power requirements can range from 12V to 24V, with different power rails for CPU, memory, I/O, and other system components.

Designing the power supply involves selecting appropriate DC-DC converters, ensuring that the power distribution is stable, and considering heat dissipation for high-power systems. The carrier board should include a robust power management solution to handle peak power demands and prevent overvoltage or undervoltage conditions.

2. Connector and Interface Selection

The COM-HPC carrier must support a wide variety of connectors to interface with external devices. The COM-HPC specification defines several key interfaces, including PCIe, USB, Ethernet, and DisplayPort, but the exact connectors used depend on the design requirements. For example, for industrial systems, you might need to include serial ports (RS232/RS485), GPIO pins, or custom I/O interfaces.

The design of the carrier board should account for connector placement, signal routing, and electrical noise considerations. Additionally, it is important to follow the COM-HPC guidelines for trace impedance, signal integrity, and shielding to ensure reliable data transmission.

3. Cooling and Thermal Management

High-performance computing modules tend to generate significant heat during operation, especially in embedded systems used for AI processing or real-time analytics. Therefore, a good COM-HPC carrier design guide will include thermal management strategies to ensure proper cooling.

Cooling solutions may include heat sinks, thermal pads, or active cooling fans. The placement of these cooling elements must be carefully considered based on the heat generation patterns of the COM-HPC module and the surrounding components. Additionally, the carrier board should be designed to optimize airflow to prevent hotspots and ensure that heat is dissipated efficiently.

4. Form Factor and Mechanical Design

COM-HPC modules are available in different form factors, including the “Basic” and “Advanced” sizes. The COM-HPC carrier must be designed to accommodate the selected module’s size and mechanical requirements, ensuring proper alignment and secure mounting.

The carrier board’s mechanical design must also consider the overall system’s size, weight, and environmental conditions. This includes ensuring proper structural integrity, shock and vibration resistance, and compatibility with mounting systems such as DIN rails or custom enclosures.

5. Signal Integrity and EMI Shielding

In any embedded system, maintaining signal integrity is crucial to avoid data loss or corruption. The COM-HPC carrier design guide should provide strategies for routing high-speed signals, such as PCIe lanes, DDR memory, and Ethernet, with minimal crosstalk or interference.

Proper EMI (electromagnetic interference) shielding is also essential, particularly in industrial applications where noise levels may be high. Designers should implement ground planes, shielded connectors, and controlled impedance traces to reduce the risk of EMI and ensure that the system operates reliably.

Steps in Designing a COM-HPC Carrier

Now that we’ve covered the key components, let’s look at the general steps involved in designing a COM-HPC carrier board:

Step 1: Select the COM-HPC Module

The first step in the design process is to select a compatible COM-HPC module that meets your performance requirements. Consider factors such as CPU type, I/O capabilities, memory configuration, and thermal characteristics. The module you choose will dictate much of the carrier board design, so careful selection is crucial.

Step 2: Determine Power Requirements

Once you’ve selected the module, the next step is to define the power requirements. Determine the voltage and current specifications for each component, including the CPU, memory, and peripheral interfaces. Select appropriate power management components like DC-DC converters, voltage regulators, and power connectors.

Step 3: Design the Carrier Board Layout

The layout of the carrier board is critical for signal integrity, cooling, and overall performance. Place connectors, capacitors, resistors, and other components according to the signal requirements and mechanical constraints. Be sure to account for trace lengths, impedances, and shielding requirements to minimize interference and signal degradation.

Step 4: Ensure Compatibility with External Devices

Consider all external devices that the system will interface with, such as displays, storage devices, or industrial sensors. Choose appropriate connectors, add necessary ports, and ensure that the carrier board can provide reliable connections to external peripherals.

Step 5: Thermal Management and Validation

Design the thermal management system to prevent overheating. This might include adding heat sinks, fans, or other cooling mechanisms. Conduct thermal simulations to evaluate the performance of the system under load and ensure the components remain within safe temperature limits.

Step 6: Prototype and Test

After completing the design, build a prototype of the carrier board and test it in a real-world environment. Perform comprehensive testing to ensure the system is stable, the power supply is sufficient, and the interfaces function correctly. If issues arise, tweak the design and retest as necessary.

FAQs About the COM-HPC Carrier Design Guide

1. What is the difference between COM-HPC and COM Express?

COM-HPC is a newer standard that offers higher performance capabilities compared to COM Express. COM-HPC modules are designed for high-performance embedded systems, featuring more powerful processors, faster data interfaces (e.g., PCIe Gen 4, USB 3.2), and increased memory support.

2. Can I use a COM Express carrier board with a COM-HPC module?

No, COM Express and COM-HPC use different form factors and connector types. A COM-HPC carrier board is specifically designed to support COM-HPC modules and cannot be used with COM Express modules directly.

3. How do I ensure signal integrity on a COM-HPC carrier board?

Signal integrity can be maintained by properly routing high-speed traces, minimizing the length of high-frequency signal paths, and using controlled impedance traces. Additionally, proper grounding and shielding should be employed to reduce noise and cross-talk.

4. What cooling solutions are available for COM-HPC carriers?

Cooling solutions for COM-HPC carrier boards include passive heat sinks, active cooling fans, and thermal pads. For high-performance systems, a combination of these methods may be used to ensure the system remains cool under heavy workloads.

5. What are the typical use cases for COM-HPC systems?

COM-HPC systems are used in a wide range of applications that require high computational power, including industrial automation, edge computing, artificial intelligence, machine learning, telecommunications, and video processing.

Conclusion

The COM-HPC carrier design guide is a critical resource for creating high-performance embedded systems that leverage the power and flexibility of the COM-HPC standard. By carefully selecting components, designing for thermal management, and ensuring compatibility with external devices, engineers can build reliable, high-performance systems for a variety of applications. Whether you’re developing for edge computing, AI, or industrial automation, understanding the design principles outlined in this guide will ensure that your carrier board is both efficient and scalable for future needs.